Home > Platform

The all-in-one solution for virtual commissioning, process analysis and optimization, as well advanced training tailored for today's and tomorrow's factories.

RF::Suite empowers your production processes by combining cutting-edge simulation tools, data analysis, and training solutions. Achieve faster commissioning, optimize workflows, and enhance decision-making with seamless integration of robotics, PLC systems, and IoT data. RF::Suite minimizes risks, reduces costs, and delivers precision across all stages of production – from planning to execution. Experience a transformative platform that redefines how industries innovate and operate.

RF::Suite empowers your production processes by combining cutting-edge simulation tools, data analysis, and training solutions. Achieve faster commissioning, optimize workflows, and enhance decision-making with seamless integration of robotics, PLC systems, and IoT data. RF::Suite minimizes risks, reduces costs, and delivers precision across all stages of production – from planning to execution. Experience a transformative platform that redefines how industries innovate and operate.

01

Shorten your commissioning time on site

02

Risk minimization in the start-up phase of a production plant

03

Optimization of production plant

04

Monitor your system and create more transparency

05

Worker support through visual assistance systems

06

Qualify your employees or suppliers for better productivity

Save time and cut costs with early-stage modeling. Traditional commissioning drains your budget and patience, especially when last-minute software errors surface. By integrating modeling early, PLC programmers ensure flawless control code. Enter data effortlessly through an editor or import from CAD programs.

This lets you quickly model and test your plant or machine in real-time. The result? A smoother, faster commissioning process, reducing time by 15 to 30 percent. Invest in efficiency from the start and watch your project succeed with fewer headaches.

Virtual Commissioning enables seamless validation of production systems before physical deployment. By simulating robotic movements, PLC programs, and workflows, you can detect and resolve issues early in the process, saving time and reducing costs. This approach minimizes risks, accelerates commissioning, and ensures a flawless start-up for your factory operations.

Optimization tools in RF::Suite analyze your production systems to enhance efficiency, reduce bottlenecks, and improve throughput. Leveraging real-time data, our solutions provide actionable insights to fine-tune workflows, increase productivity, and maximize output while reducing energy consumption.

With RF::Suite's advanced monitoring capabilities, gain unparalleled visibility into your production line. Real-time dashboards display critical metrics such as performance, cycle times, and machine health. This transparency enables proactive maintenance, prevents downtime, and ensures a steady production flow.

RF::Suite revolutionizes training with immersive virtual environments. Employees can safely learn to operate machinery, handle complex scenarios, and troubleshoot faults using realistic simulations. This approach enhances skill development, reduces learning curves, and boosts overall workforce competence.

01

Accelerate Your Processes

Reduce commissioning times significantly with virtual validation, streamlined optimization, and enhanced production quality.

02

Increase Operational Efficiency and Quality

Monitor, analyze, and enhance your production systems with real-time data and actionable insights to improve operational efficiency and ensure top-quality results

03

Future-Proof Technology

Harness the power of cutting-edge tools for digital twins, simulation, and data integration to stay ahead in a rapidly evolving industry while maintaining the highest quality standards.

04

Unmatched Flexibility

Modular tools tailored to your specific needs, from virtual commissioning to detailed monitoring and employee training, ensuring consistent quality improvements.

05

Trusted by Industry Leaders

With decades of experience and proven success, RF::Suite is used by leading factories worldwide to improve quality, productivity, and operational excellence.

Key components of the RF::Suite, providing advanced features for simulation, optimization, and digital twin integration within manufacturing processes.

Simulates production systems in a 3D virtual environment, offering deep insights into system performance, potential optimizations, and operational efficiency.

Models, simulates, and tests peripheral elements in virtual commissioning using reusable program blocks for enhanced flexibility and efficiency.

Provides advanced robot simulation capabilities for testing and optimizing robot programs, ensuring error-free commissioning and efficient workflows.

Analyzes production data from virtual and real systems to identify bottlenecks, optimize performance, and enhance production efficiency.

Automates 3D fixture design with editable models, ensuring maximum flexibility for designers and improved production workflows.

Simulates Profinet devices for virtual commissioning, allowing seamless testing of multiple PLC controllers within a single environment.

Empower Workforce Education with Virtual Training for Real-World Skills

Our suite of products boasts a diverse array of tools, from PLC and robot connectors to advanced automation and educational resources. Yet, at its heart, we have a core set of tools that seamlessly integrate everything, creating a powerful and cohesive system.

Simulates production systems in a 3D virtual environment, offering deep insights into system performance, potential optimizations, and operational efficiency.

Models, simulates, and tests peripheral elements in virtual commissioning using reusable program blocks for enhanced flexibility and efficiency.

Provides advanced robot simulation capabilities for testing and optimizing robot programs, ensuring error-free commissioning and efficient workflows.

Analyzes production data from virtual and real systems to identify bottlenecks, optimize performance, and enhance production efficiency.

Key differences between other solutions

Key differences between other solutions

Similar products

Limited Simulation Scope: Restricted to handling a small number of production lines at once.

Fragmented Toolset: Requires multiple tools to achieve comprehensive results, leading to inefficiencies.

Lack of Training Integration: No built-in training or educational modules for users.

Manual Setup Required: Extensive configuration needed, slowing down deployment.

Low Customization Options: Minimal adaptability to specific project needs.

RF::Suite

Comprehensive All-in-One Solution: Simulates entire factories, integrating robotics, PLCs, and IoT seamlessly.

Modular and Scalable: Flexible architecture that grows with your needs.

Industry-Leading Support: Backed by 25 years of experience and a dedicated team of experts.

Plug-and-Play Ready: Enables direct use of safety systems, cameras, and other features without additional setup.

Cloud Integration: Offers remote operations, monitoring, and optimization anytime, anywhere.

Training and Assistance Tools: Built-in modules for quick guidance and employee skill development.

Cross-System Compatibility: Works across PLCs, robots, and other devices, ensuring maximum adaptability.

PLC Programmer

01

Validate and test control programs before deployment.

Reduced travel requirements with virtual testing capabilities.

Stress-free workflow by identifying potential errors beforehand.

Familiarize with production plant processes and functions in advance.

Improved data quality through precise simulation.

Compliance with automation standards and regulations

Robot Programmer

02

Test and optimize motion paths in a simulated environment.

Prevent collisions and errors during programming.

Seamless integration with PLCs and other control systems even at an early stage.

Efficient development with offline programming tools.

Simulate multiple scenarios to find the most efficient solution.

System planner

03

Visualize entire production lines for optimal layout planning.

Utilize realistic 3D models to evaluate space requirements and efficiency.

Simulate material flow and optimize production processes.

Reduce planning errors through virtual commissioning.

Maintenance personel

04

Access to digital twins of production facilities for detailed troubleshooting.

Simulate faults and resolutions in a safe environment.

Shortened diagnostic times with clear data analysis and sensor integration.

Train on virtual models without disrupting ongoing production.

Educators and Trainers

05

Provide a safe learning environment for students and trainees.

Access realistic simulations without the need for costly hardware.

Enable interactive training scenarios with immediate feedback.

Customizable content for various experience levels.

Production managers

06

Precise overview of production processes and bottlenecks.

Tools to analyze and optimize cycle times and throughput.

Minimized downtime by early identification of potential issues.

Data-driven decision-making with comprehensive process analysis.

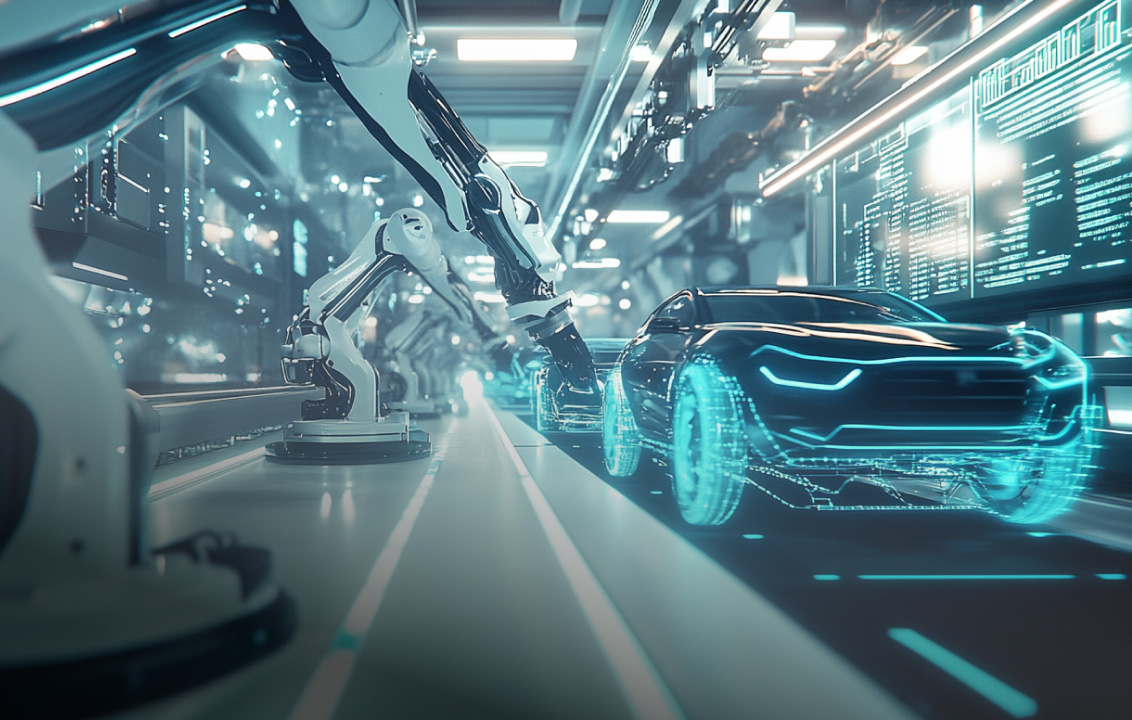

Automotive manufacturing

Aerospace engineering

Energy solutions

Medical Applications

Driving the Future of Automotive Innovation

Integrating cutting-edge automation and smart technologies to revolutionize automotive manufacturing and mobility solutions.

Explore Automotive manufacturingDriving the Future of Automotive Innovation

Explore Automotive manufacturing

Have a project in mind?

China,

Shanghai

Germany,

Weingarten

Bosnia,

Tuzla

India,

Bangalore

Montenegro,

Podgorica

China, Shanghai

Germany, Weingarten

Bosnia, Tuzla

India, Bangalore

Montenegro, Podgorica

We use cookies and other tracking technologies to improve your browsing experience on our website, to show you personalized content and targeted ads, to analyze our website traffic, and to understand where our visitors are coming from.