Home > Services > Digitale Fabrik > Digitale Fabrik > Virtuelle Inbetriebnahme

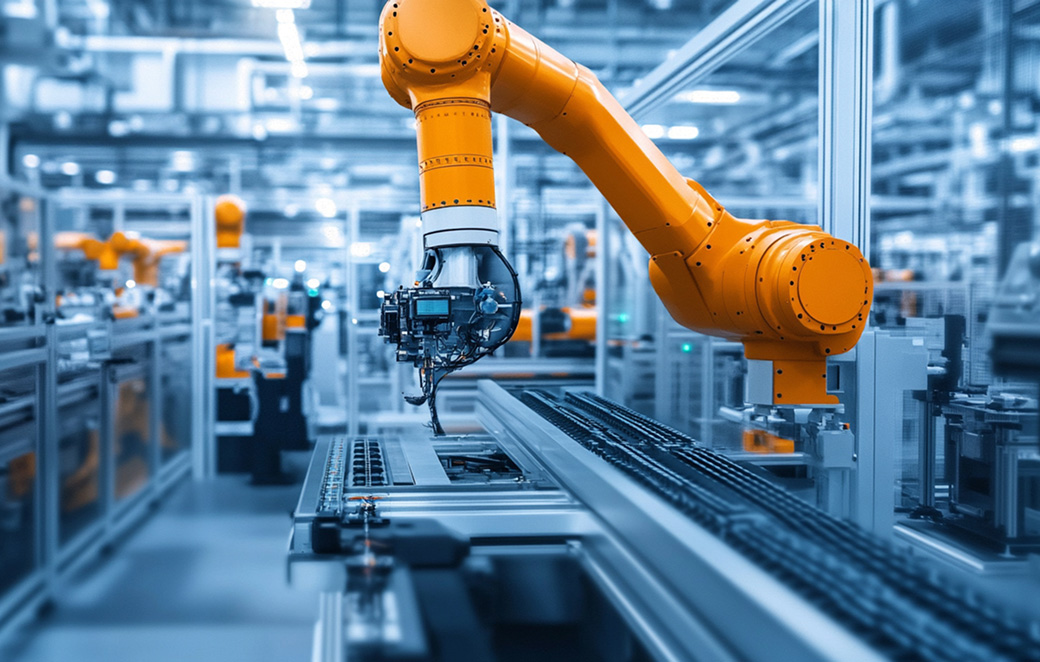

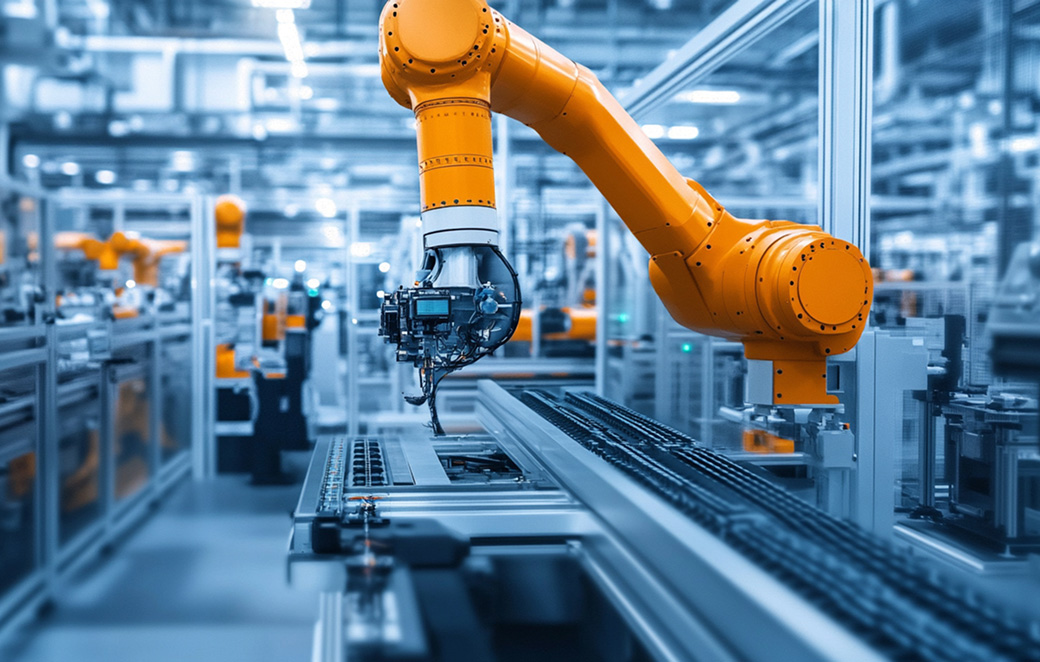

Unsere Technologie zur virtuellen Inbetriebnahme revolutioniert die Produktionsplanung, indem Systeme simuliert, validiert und optimiert werden können, bevor physische Komponenten installiert sind.

Dadurch profitieren Sie von fehlerfreien Inbetriebnahmen, beschleunigten Zeitplänen und deutlich reduzierten Umsetzungskosten – alles ermöglicht durch intelligente digitale Voraussicht.

Die virtuelle Inbetriebnahme ermöglicht das Debuggen und Testen von SPS- und Roboterprogrammen in einer digitalen Umgebung.

So wird sichergestellt, dass Ihre Automatisierungssoftware vor dem Einsatz auf der physischen Hardware vollständig validiert ist. Zudem können Steuerlogiken integriert und unter realen Bedingungen getestet werden.

Sicherheitssysteme werden ebenfalls virtuell überprüft, wodurch die Einhaltung von Standards gewährleistet und Risiken bei der Inbetriebnahme reduziert werden.

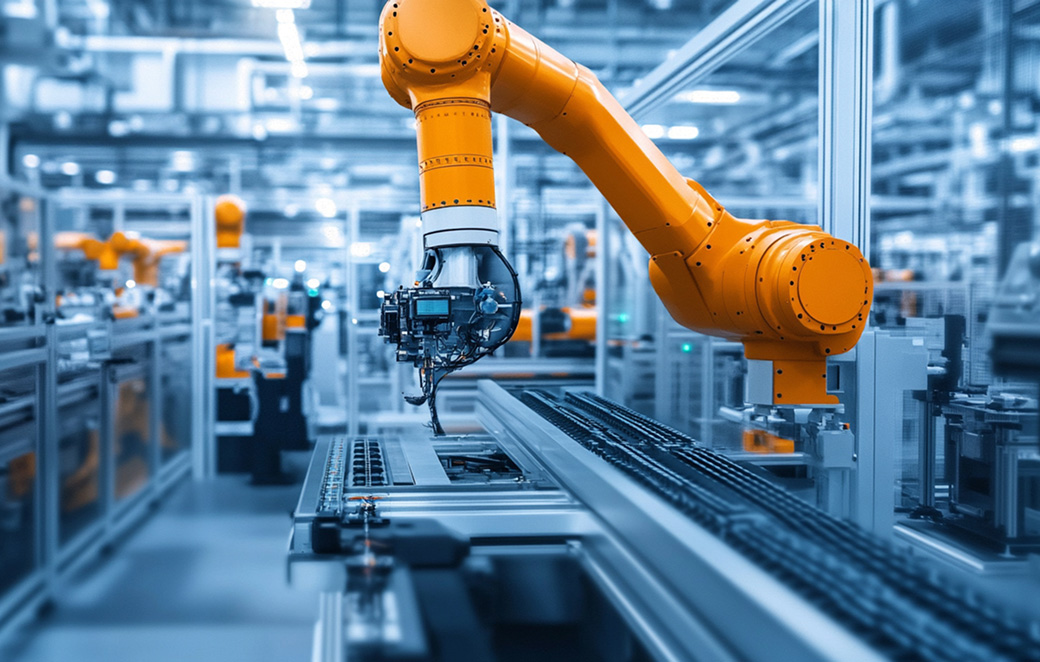

Durch die Simulation mechanischer, elektrischer und pneumatischer Prozesse validieren wir die Systemfunktionalität bereits in der frühen Entwurfsphase.

Zusätzlich liefert die Digital-Twin-Technologie umfassende Einblicke in das reale Verhalten, ermöglicht eine frühzeitige Fehlererkennung und reduziert Ineffizienzen.

Das Factory Acceptance Testing (FAT) wird virtuell durchgeführt, um sicherzustellen, dass Ihre Systeme alle Anforderungen erfüllen, bevor sie in Betrieb gehen.

Die Zykluszeitverifikation hilft, Engpässe zu erkennen und den Produktionsdurchsatz vor der Inbetriebnahme zu optimieren.

Darüber hinaus reduzieren Energie- und Durchsatzoptimierung den Verbrauch und verbessern die Nachhaltigkeit bereits in der Planungsphase.

Feedback nach der Inbetriebnahme ermöglicht eine kontinuierliche Verbesserung durch Verfeinerung digitaler Modelle und Steigerung der Gesamtleistung des Systems.

Die virtuelle Inbetriebnahme ermöglicht das Debuggen und Testen von SPS- und Roboterprogrammen in einer digitalen Umgebung.

So wird sichergestellt, dass Ihre Automatisierungssoftware vor dem Einsatz auf der physischen Hardware vollständig validiert ist. Zudem können Steuerlogiken integriert und unter realen Bedingungen getestet werden.

Sicherheitssysteme werden ebenfalls virtuell überprüft, wodurch die Einhaltung von Standards gewährleistet und Risiken bei der Inbetriebnahme reduziert werden.

Durch die Simulation mechanischer, elektrischer und pneumatischer Prozesse validieren wir die Systemfunktionalität bereits in der frühen Entwurfsphase.

Zusätzlich liefert die Digital-Twin-Technologie umfassende Einblicke in das reale Verhalten, ermöglicht eine frühzeitige Fehlererkennung und reduziert Ineffizienzen.

Das Factory Acceptance Testing (FAT) wird virtuell durchgeführt, um sicherzustellen, dass Ihre Systeme alle Anforderungen erfüllen, bevor sie in Betrieb gehen.

Die Zykluszeitverifikation hilft, Engpässe zu erkennen und den Produktionsdurchsatz vor der Inbetriebnahme zu optimieren.

Darüber hinaus reduzieren Energie- und Durchsatzoptimierung den Verbrauch und verbessern die Nachhaltigkeit bereits in der Planungsphase.

Feedback nach der Inbetriebnahme ermöglicht eine kontinuierliche Verbesserung durch Verfeinerung digitaler Modelle und Steigerung der Gesamtleistung des Systems.

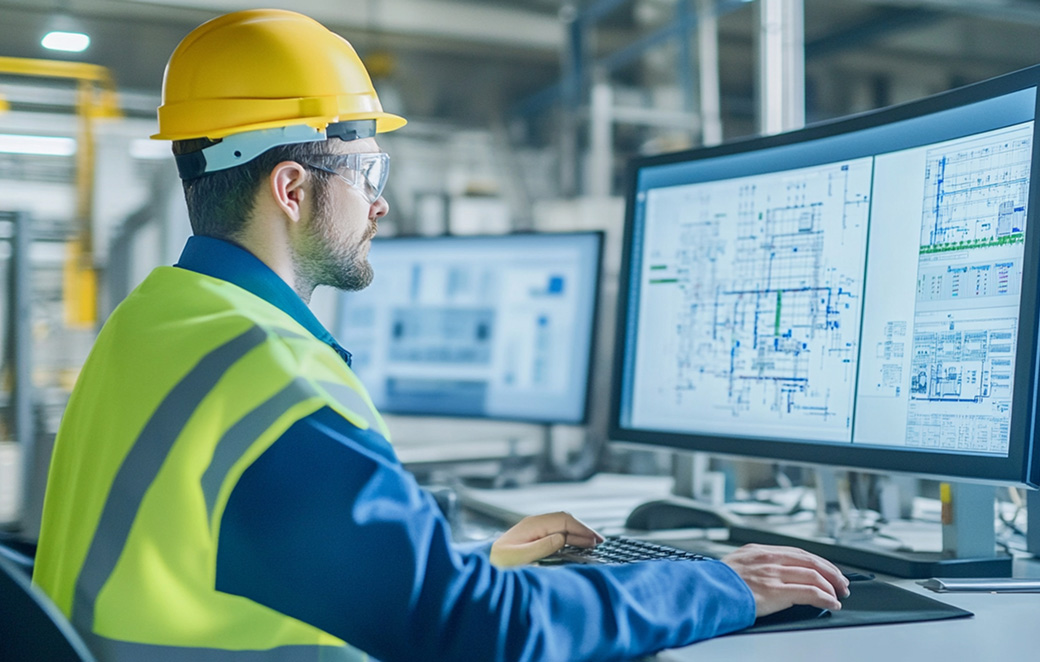

Das Debuggen und Testen ermöglicht es, SPS- und Roboterprogramme in einer virtuellen Umgebung zu prüfen, sodass die Software fehlerfrei ist, bevor sie auf der physischen Hardware eingesetzt wird.

Die Integration von Steuerlogik ermöglicht das Einbinden und Testen von SPS- und Robotersteuerungen mit einem digitalen Modell, wobei Steuerabläufe und Systemverhalten unter verschiedenen Szenarien simuliert werden.

Sicherheitssysteme werden virtuell validiert, wodurch die Einhaltung von Branchenstandards gewährleistet wird, ohne dass physische Hardware erforderlich ist.

Simulation mechanischer, elektrischer und pneumatischer Prozesse zur Validierung der Funktionalität vor der Implementierung.

Der Einsatz der Digital-Twin-Technologie ermöglicht Einblicke in das reale Verhalten und eine frühzeitige Erkennung von Fehlern und Ineffizienzen.

Das Factory Acceptance Testing stellt sicher, dass Systeme die Anforderungen erfüllen, indem Prozesse virtuell validiert werden. Dadurch werden die Risiken herkömmlicher Inbetriebnahmen reduziert.

Die Zykluszeitverifikation überprüft die Zykluszeiten und identifiziert Engpässe, um die Produktionseffizienz zu optimieren.

Die Energie- und Durchsatzoptimierung ermöglicht die virtuelle Optimierung von Energieverbrauch und Durchsatzzeiten bereits in der Entwurfsphase.

Kontinuierliche Verbesserung durch Feedback nach der Inbetriebnahme wird genutzt, um digitale Modelle zu verfeinern und die Systemleistung weiter zu steigern.

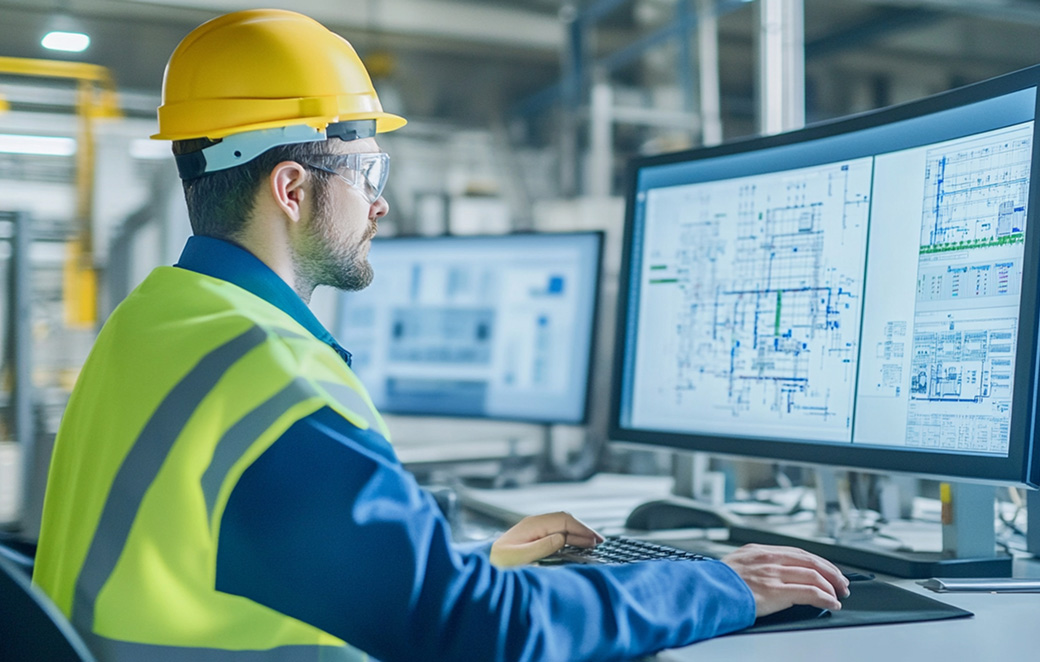

Wir unterstützen Ihre Pilotprojekte mit fachkundiger Beratung und enger Zusammenarbeit. So kann Ihr Team virtuelle Inbetriebnahmen auch bei komplexen Herausforderungen erfolgreich umsetzen – selbst bei der erstmaligen Anwendung.

Durch die Zusammenarbeit mit unseren Expertenteams erhalten Sie Zugang zu spezialisierten Kompetenzen und modernsten Technologien. So wird Ihr Automatisierungsprozess schneller, zuverlässiger und genau auf Ihre Anforderungen zugeschnitten.

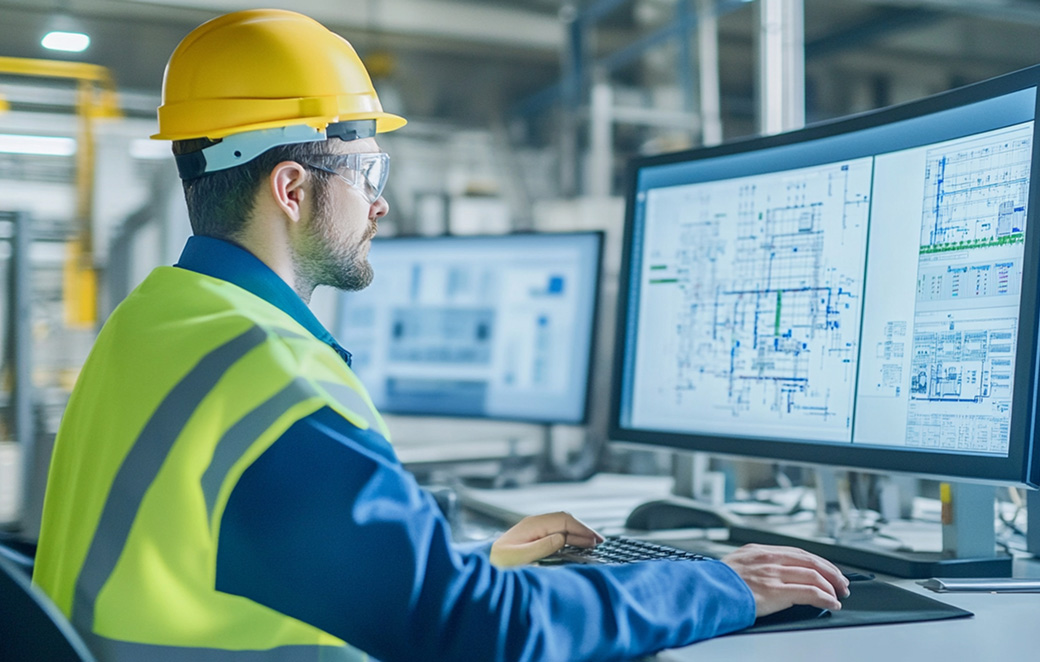

Wir beginnen mit der Analyse Ihrer bestehenden Engineering-Workflows, um klare Ziele für die virtuelle Inbetriebnahme zu definieren.

Anschließend erstellen wir digitale Zwillinge, führen Simulationen durch und automatisieren zentrale Aufgaben. Während des gesamten Prozesses fördern wir die bereichsübergreifende Zusammenarbeit und setzen ROI-orientierte Teststrategien ein.

Letztlich verbessert dies Ihre Engineering-Leistung und maximiert die Vorteile der Arbeit in virtuellen Umgebungen.

Optimierung des Engineering-Workflows

Best-in-Class Werkzeuge für virtuelle Inbetriebnahme

Haben Sie eine Projektidee?

Fabrikmodellierung

China,

Shanghai

Deutschland,

Weingarten

Bosnien,

Tuzla

Indien,

Bangalore

Montenegro,

Podgorica

China, Shanghai

Deutschland, Weingarten

Bosnien, Tuzla

Indien, Bangalore

Montenegro, Podgorica

Wir verwenden Cookies und andere Tracking-Technologien, um Ihr Nutzungserlebnis auf unserer Website zu verbessern, personalisierte Inhalte und gezielte Werbung anzuzeigen, den Website-Traffic zu analysieren und zu verstehen, woher unsere Besucher kommen.