Home > Plattform > Produkte > RF::GUARD

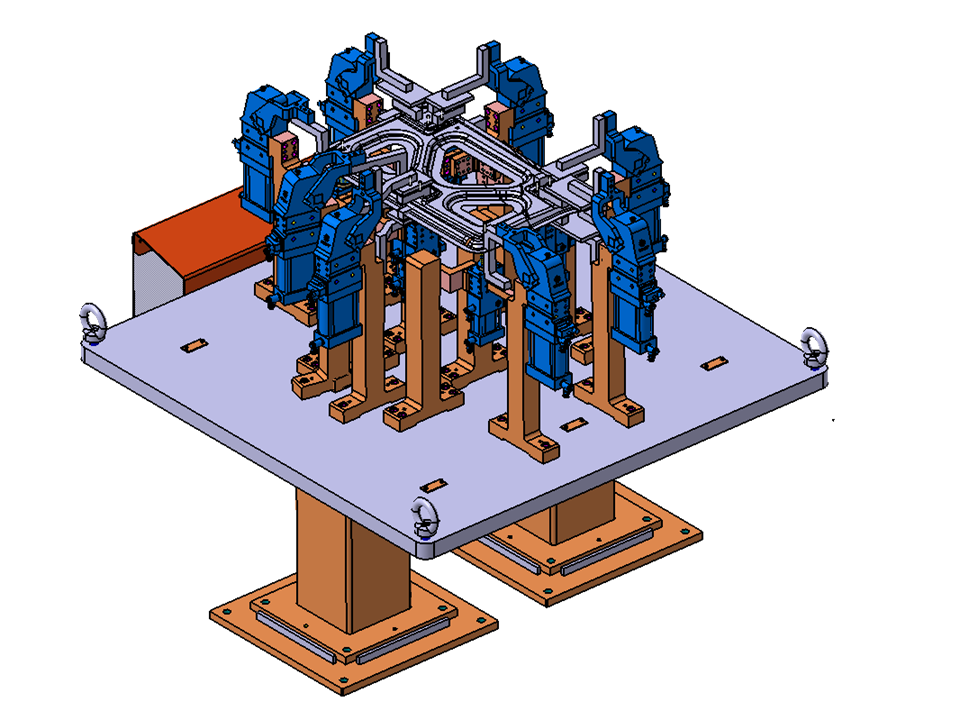

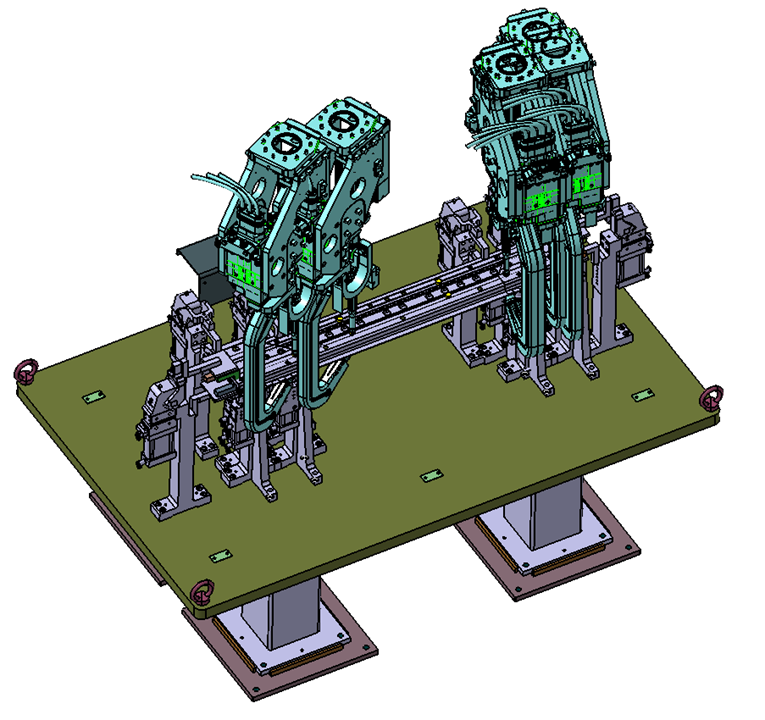

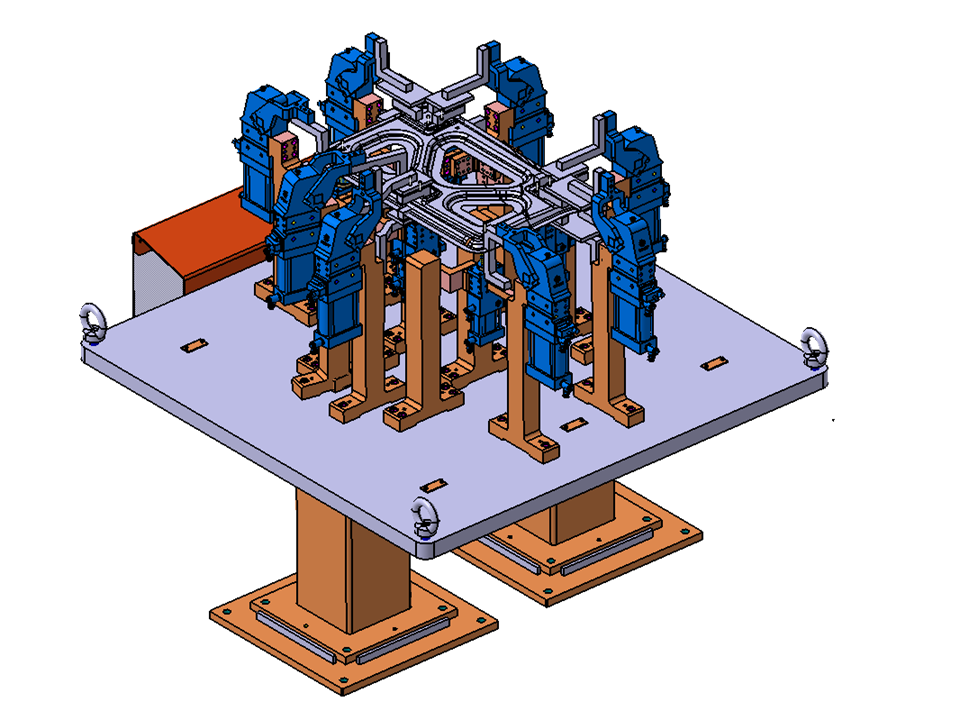

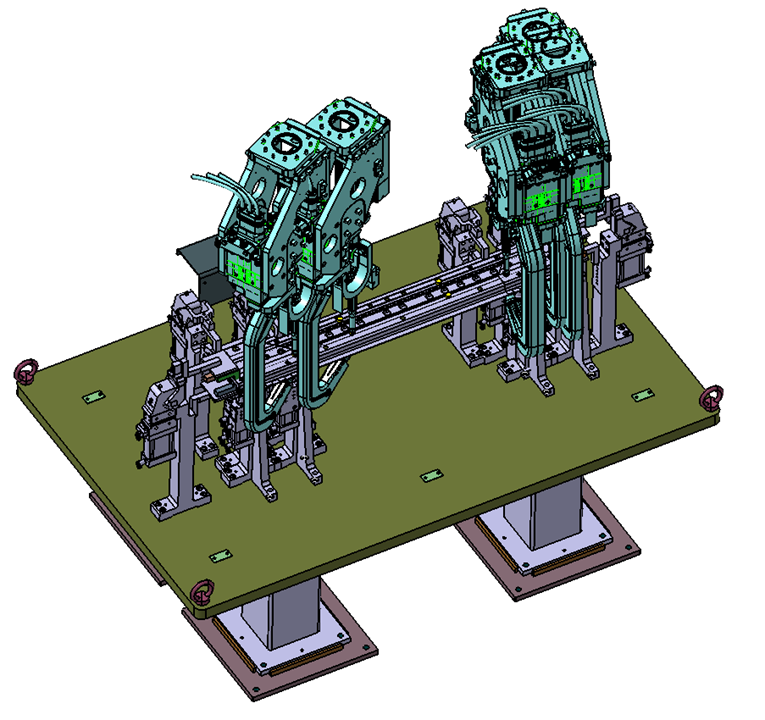

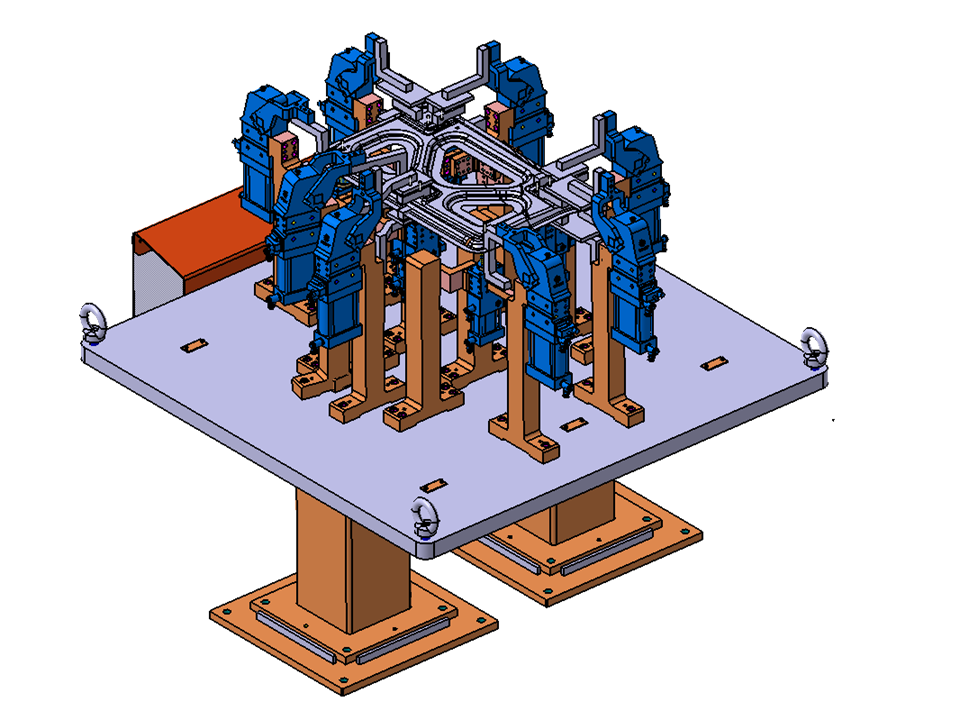

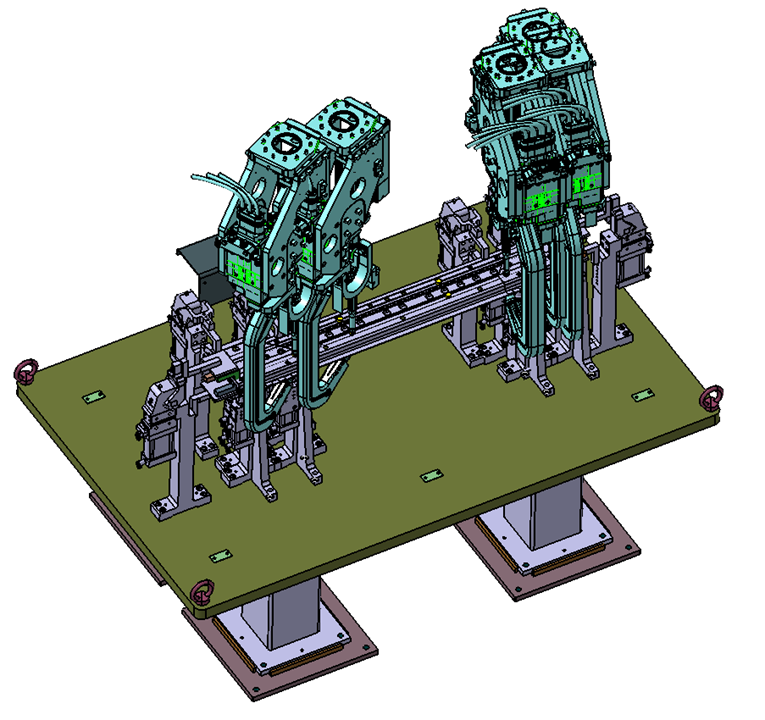

Unsere RF::GUARD Software ermöglicht die automatische Erstellung von Vorrichtungen in 3D innerhalb kürzester Zeit. Dank eines nativen CAD-Daten-Exporters können die generierten Modelle direkt bearbeitet werden, was Designern maximale Flexibilität bietet. Die Entwürfe lassen sich anschließend problemlos in gängige CAD/CAM-Systeme wie CATIA oder NX integrieren und individuell anpassen.

Erstellen Sie 3D-Konzepte für Vorrichtungen in Rekordzeit und verkürzen Sie so Ihre Projektlaufzeiten.

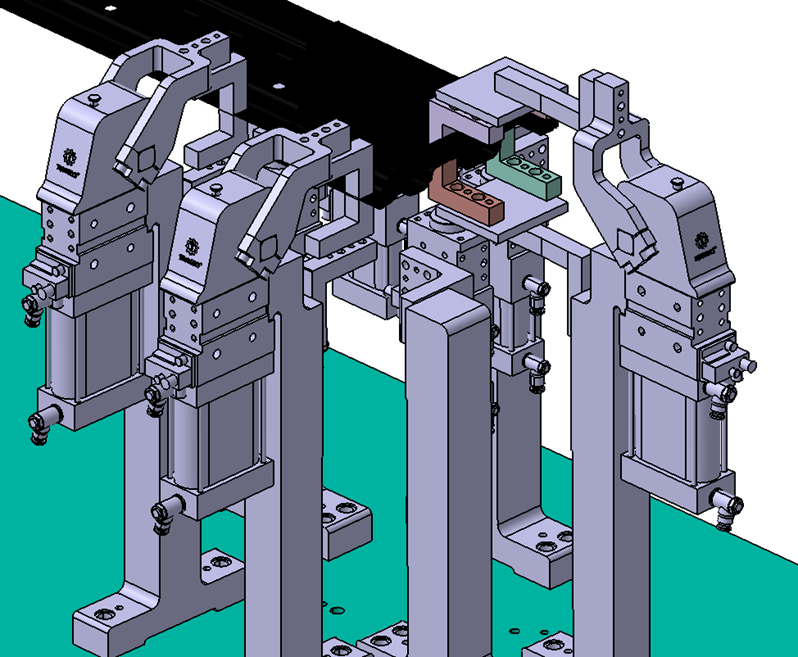

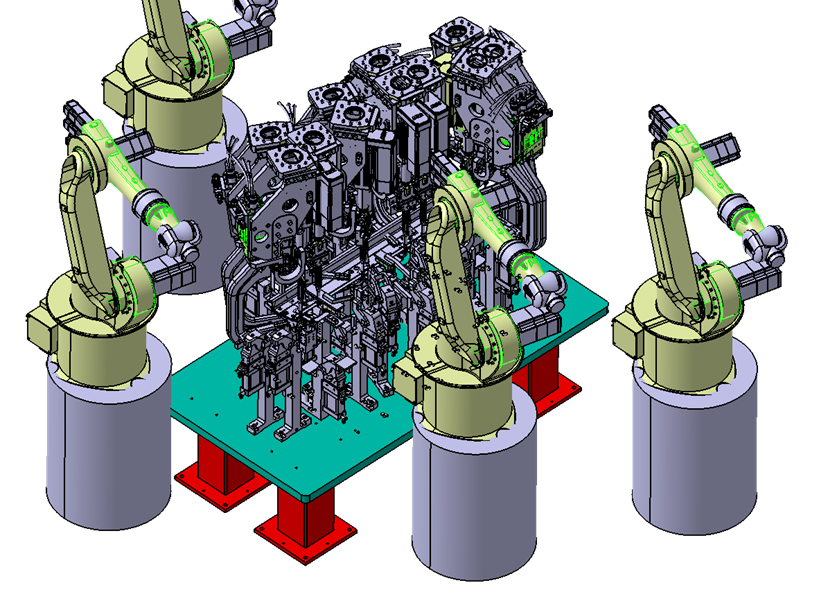

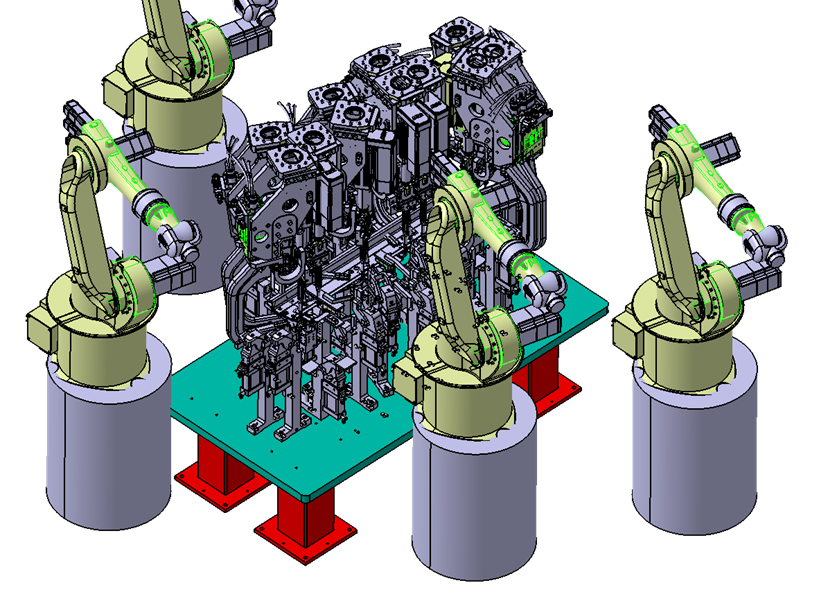

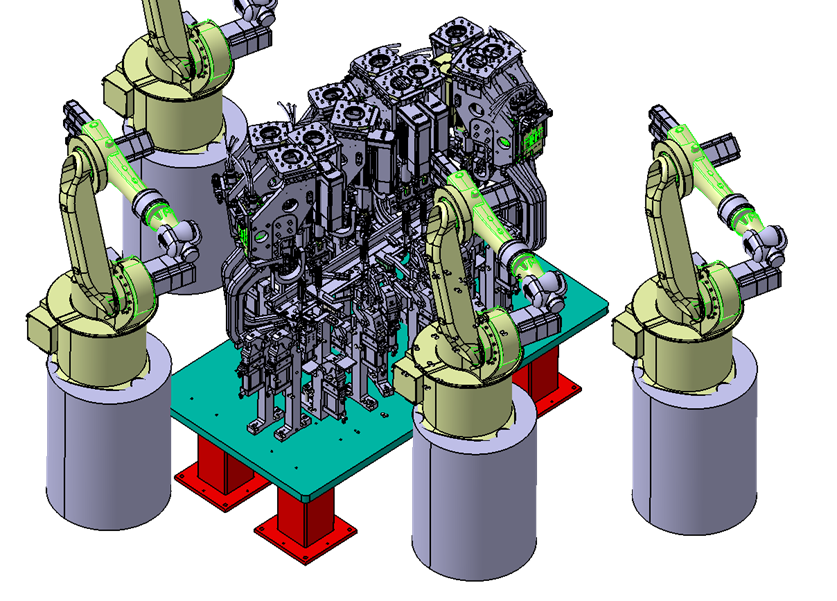

Sichern Sie eine sichere Positionierung von Roboter und Werkzeug durch integrierte Kollisionsprüfungs-Algorithmen.

Minimieren Sie den Aufwand für Vorbereitung in Konstruktions- und Simulationsabläufen.

Reduzieren Sie Iterationsschleifen zwischen Konstruktions- und Simulationsteams und verbessern Sie so die Zusammenarbeit.

Sparen Sie Engineering-Kosten durch effiziente und automatisierte Konstruktionsprozesse.

Kosten- und Zeitersparnis in Projekten

RF::GUARD revolutioniert die Vorrichtungskonstruktion, indem es die schnelle Erstellung präziser und effizienter 3D-Modelle ermöglicht. Durch die Automatisierung komplexer Geometrien können Anwender die Konstruktionszeit deutlich verkürzen und die Produktivität steigern. Diese Funktion ist besonders wertvoll für Projekte mit kurzen Durchlaufzeiten, bei denen jede Sekunde zählt. Dank der schnellen Modellierungsfunktionen von RF::GUARD bleiben höchste Qualitätsstandards auch bei engen Zeitplänen gewährleistet.

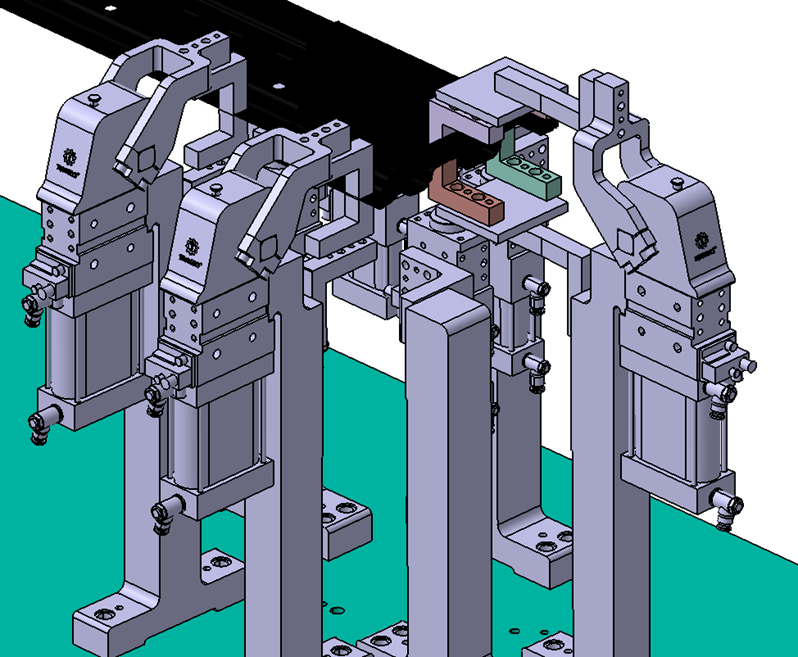

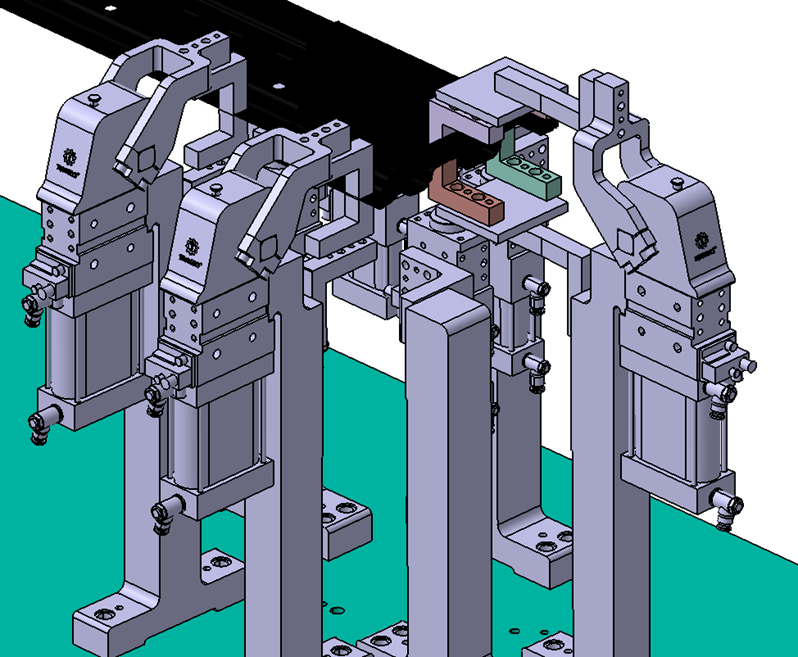

Die Kollisionsprüfungsfunktion von RF::GUARD stellt sicher, dass potenzielle Probleme bereits in der Konstruktionsphase erkannt und behoben werden. Durch die Simulation der Positionierung von Robotern, Werkzeugen und Vorrichtungen in der virtuellen Umgebung werden Konflikte frühzeitig sichtbar, sodass teure Anpassungen vermieden werden. Dieser proaktive Ansatz zur Validierung steigert die Sicherheit und Zuverlässigkeit von Produktionssystemen.

RF::GUARD verkürzt die Vorbereitungszeit für die Vorrichtungskonstruktion drastisch, indem wiederkehrende und zeitaufwändige Aufgaben automatisiert werden. Die Software vereinfacht den Übergang vom Konzept zur Umsetzung und ermöglicht die Erstellung einsatzbereiter 3D-Modelle in Rekordzeit. Durch optimierte Workflows und weniger manuelle Eingriffe sorgt RF::GUARD dafür, dass Projekte termingerecht und ohne Qualitätsverlust abgeschlossen werden.

RF::GUARD eliminiert unnötige Abstimmungsschleifen zwischen Konstruktions- und Simulationsteams, indem alle wichtigen Funktionen in einer Plattform integriert werden. Dank der intuitiven Benutzeroberfläche und intelligenten Features können Abteilungen nahtlos zusammenarbeiten, Ineffizienzen reduzieren und Verzögerungen minimieren. So wird ein reibungsloser Übergang zwischen den Teams gewährleistet und die Produktivität sowie die Abstimmung insgesamt verbessert.

RF::GUARD reduziert Kosten und Zeit erheblich, indem der Konstruktionsprozess optimiert wird. Teams können so hochwertige Designs effizienter und standardisierter erstellen. Durch die Automatisierung wiederkehrender Aufgaben und den Zugriff auf Vorlagen und Ressourcen können sich Designer auf die innovativen Aspekte ihrer Entwürfe konzentrieren.

RF::GUARD revolutioniert die Vorrichtungskonstruktion, indem es die schnelle Erstellung präziser und effizienter 3D-Modelle ermöglicht. Durch die Automatisierung komplexer Geometrien können Anwender die Konstruktionszeit deutlich verkürzen und die Produktivität steigern. Diese Funktion ist besonders wertvoll für Projekte mit kurzen Durchlaufzeiten, bei denen jede Sekunde zählt. Dank der schnellen Modellierungsfunktionen von RF::GUARD bleiben höchste Qualitätsstandards auch bei engen Zeitplänen gewährleistet.

Die Kollisionsprüfungsfunktion von RF::GUARD stellt sicher, dass potenzielle Probleme bereits in der Konstruktionsphase erkannt und behoben werden. Durch die Simulation der Positionierung von Robotern, Werkzeugen und Vorrichtungen in der virtuellen Umgebung werden Konflikte frühzeitig sichtbar, sodass teure Anpassungen vermieden werden. Dieser proaktive Ansatz zur Validierung steigert die Sicherheit und Zuverlässigkeit von Produktionssystemen.

RF::GUARD verkürzt die Vorbereitungszeit für die Vorrichtungskonstruktion drastisch, indem wiederkehrende und zeitaufwändige Aufgaben automatisiert werden. Die Software vereinfacht den Übergang vom Konzept zur Umsetzung und ermöglicht die Erstellung einsatzbereiter 3D-Modelle in Rekordzeit. Durch optimierte Workflows und weniger manuelle Eingriffe sorgt RF::GUARD dafür, dass Projekte termingerecht und ohne Qualitätsverlust abgeschlossen werden.

RF::GUARD eliminiert unnötige Abstimmungsschleifen zwischen Konstruktions- und Simulationsteams, indem alle wichtigen Funktionen in einer Plattform integriert werden. Dank der intuitiven Benutzeroberfläche und intelligenten Features können Abteilungen nahtlos zusammenarbeiten, Ineffizienzen reduzieren und Verzögerungen minimieren. So wird ein reibungsloser Übergang zwischen den Teams gewährleistet und die Produktivität sowie die Abstimmung insgesamt verbessert.

RF::GUARD reduziert Kosten und Zeit erheblich, indem der Konstruktionsprozess optimiert wird. Teams können so hochwertige Designs effizienter und standardisierter erstellen. Durch die Automatisierung wiederkehrender Aufgaben und den Zugriff auf Vorlagen und Ressourcen können sich Designer auf die innovativen Aspekte ihrer Entwürfe konzentrieren.

RF::GUARD revolutioniert die Vorrichtungskonstruktion, indem es die schnelle Erstellung präziser und effizienter 3D-Modelle ermöglicht. Durch die Automatisierung komplexer Geometrien können Anwender die Konstruktionszeit deutlich verkürzen und die Produktivität steigern. Diese Funktion ist besonders wertvoll für Projekte mit kurzen Durchlaufzeiten, bei denen jede Sekunde zählt. Dank der schnellen Modellierungsfunktionen von RF::GUARD bleiben höchste Qualitätsstandards auch bei engen Zeitplänen gewährleistet.

Die Kollisionsprüfungsfunktion von RF::GUARD stellt sicher, dass potenzielle Probleme bereits in der Konstruktionsphase erkannt und behoben werden. Durch die Simulation der Positionierung von Robotern, Werkzeugen und Vorrichtungen in der virtuellen Umgebung werden Konflikte frühzeitig erkannt und kostspielige Anpassungen vermieden. Dieser proaktive Ansatz zur Validierung steigert sowohl die Sicherheit als auch die Zuverlässigkeit von Produktionssystemen.

RF::GUARD verkürzt die Vorbereitungszeit für die Vorrichtungskonstruktion drastisch, indem wiederkehrende und zeitaufwändige Aufgaben automatisiert werden. Die Software vereinfacht den Übergang vom Konzept zur Umsetzung und ermöglicht die Erstellung einsatzbereiter 3D-Modelle in Rekordzeit. Durch optimierte Workflows und weniger manuelle Eingriffe sorgt RF::GUARD dafür, dass Projekte termingerecht und ohne Qualitätsverlust abgeschlossen werden.

RF::GUARD eliminiert unnötige Abstimmungsschleifen zwischen Konstruktions- und Simulationsteams, indem alle wichtigen Funktionen in einer Plattform integriert werden. Dank der intuitiven Benutzeroberfläche und intelligenten Features können Abteilungen nahtlos zusammenarbeiten, Ineffizienzen reduzieren und Verzögerungen minimieren. So wird ein reibungsloser Übergang zwischen den Teams gewährleistet und die Produktivität sowie die Abstimmung insgesamt verbessert.

RF::GUARD reduziert Kosten und Zeit erheblich, indem der Konstruktionsprozess gestrafft wird. Teams können so hochwertige Designs effizienter und standardisierter erstellen. Durch die Automatisierung wiederkehrender Aufgaben und den Zugriff auf Vorlagen und Ressourcen können sich Designer auf die innovativen Bestandteile ihrer Entwürfe konzentrieren.

Unsere Produktpalette umfasst vielfältige Werkzeuge – von SPS- und Roboteranschlüssen bis hin zu fortschrittlicher Automatisierung und Schulungsressourcen. Im Kern steht dabei eine zentrale Tool-Suite, die alle Komponenten nahtlos verbindet und so ein leistungsstarkes, durchgängiges System schafft.

Simuliert Produktionssysteme in einer 3D-Virtual-Environment und liefert detaillierte Einblicke in Systemleistung, Optimierungspotenziale und Betriebseffizienz.

Modelliert, simuliert und testet Peripheriekomponenten in der virtuellen Inbetriebnahme – mit wiederverwendbaren Programmbausteinen für mehr Flexibilität und Effizienz.

Bietet fortschrittliche Robotersimulation zur Prüfung und Optimierung von Roboterprogrammen – für fehlerfreie Inbetriebnahme und effiziente Abläufe.

Analysiert Produktionsdaten aus virtuellen und realen Systemen, um Engpässe zu erkennen, die Leistung zu optimieren und die Produktionseffizienz zu steigern.

Automatisiert die 3D-Vorrichtungsplanung mit bearbeitbaren Modellen – für maximale Flexibilität der Konstrukteure und optimierte Produktionsabläufe.

Simuliert Profinet-Geräte für die virtuelle Inbetriebnahme und ermöglicht nahtloses Testen mehrerer SPS-Steuerungen in einer einzigen Umgebung.

Unsere Produktpalette umfasst vielfältige Werkzeuge – von SPS- und Roboteranschlüssen bis hin zu fortschrittlicher Automatisierung und Schulungsressourcen. Im Kern steht dabei eine zentrale Tool-Suite, die alle Komponenten nahtlos verbindet und so ein leistungsstarkes, durchgängiges System schafft.

Simuliert Produktionssysteme in einer 3D-Virtual-Environment und liefert detaillierte Einblicke in Systemleistung, Optimierungspotenziale und Betriebseffizienz.

Modelliert, simuliert und testet Peripheriekomponenten in der virtuellen Inbetriebnahme – mit wiederverwendbaren Programmbausteinen für mehr Flexibilität und Effizienz.

Bietet fortschrittliche Robotersimulation zur Prüfung und Optimierung von Roboterprogrammen – für fehlerfreie Inbetriebnahme und effiziente Abläufe.

Analysiert Produktionsdaten aus virtuellen und realen Systemen, um Engpässe zu erkennen, die Leistung zu optimieren und die Produktionseffizienz zu steigern.

Automatisiert die 3D-Vorrichtungsplanung mit bearbeitbaren Modellen – für maximale Flexibilität der Konstrukteure und optimierte Produktionsabläufe.

Simuliert Profinet-Geräte für die virtuelle Inbetriebnahme und ermöglicht nahtloses Testen mehrerer SPS-Steuerungen in einer einzigen Umgebung.

Analysiert Produktionsdaten aus virtuellen und realen Systemen, um Engpässe zu erkennen, die Leistung zu optimieren und die Produktionseffizienz zu steigern.

Haben Sie eine Projektidee?

China,

Shanghai

Deutschland,

Weingarten

Bosnien,

Tuzla

Indien,

Bangalore

Montenegro,

Podgorica

China, Shanghai

Deutschland, Weingarten

Bosnien, Tuzla

Indien, Bangalore

Montenegro, Podgorica

Wir verwenden Cookies und andere Tracking-Technologien, um Ihr Nutzungserlebnis auf unserer Website zu verbessern, personalisierte Inhalte und gezielte Werbung anzuzeigen, den Website-Traffic zu analysieren und zu verstehen, woher unsere Besucher kommen.