Home > Plattform > Produkte > RF::EdDi

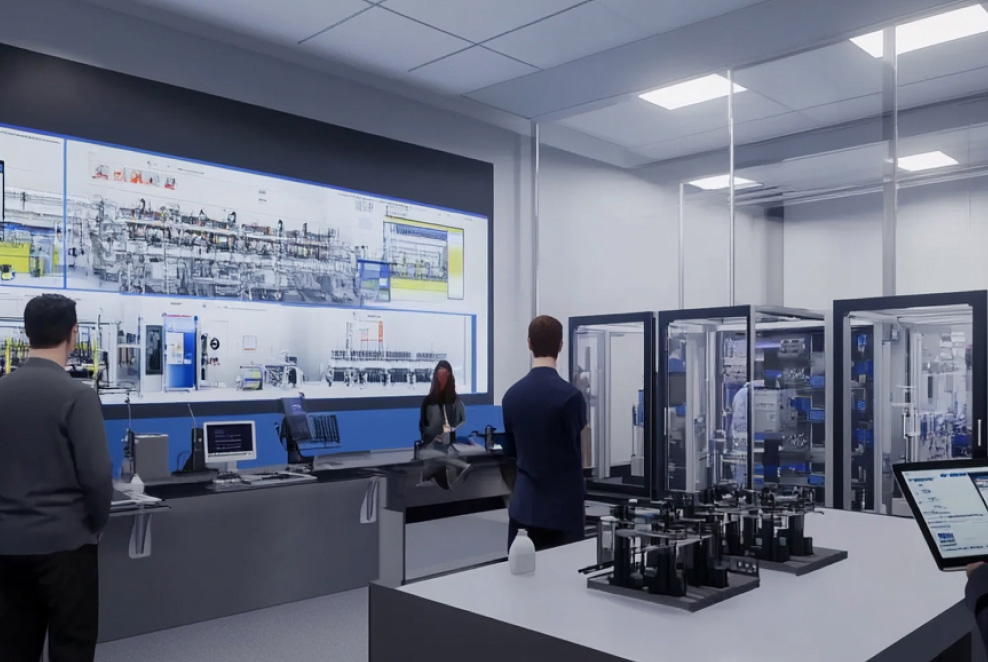

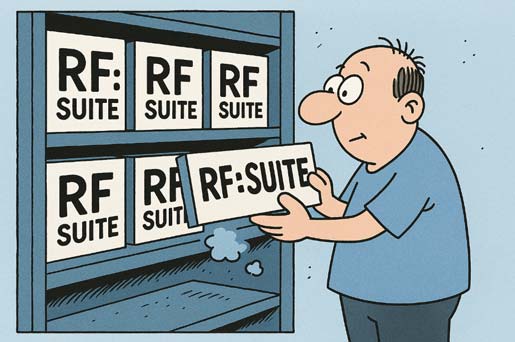

RF::EdDi ist die fortschrittliche Trainingslösung der RF::Suite-Familie und revolutioniert die Art und Weise, wie Mitarbeitende industrielle Systeme erlernen und bedienen. Mithilfe von 3D-Simulation und Verhaltensmodellierung bietet RF::EdDi eine realistische, kosteneffiziente und flexible Trainingsumgebung. Von der Simulation von Fehlerszenarien bis hin zur Visualisierung von Echtzeitsteuerungen stellt RF::EdDi eine umfassende Plattform bereit, um Mitarbeitende zu schulen, Fähigkeiten zu optimieren und die Betriebssicherheit zu erhöhen.

Realistische virtuelle Abbildungen von Anlagen und Prozessen.

- Möglichkeit, die Anlage manuell zu starten und zu steuern.

- Steuerungselemente interaktiv in einer 3D-Umgebung ausführen.

Das Verhalten von Ressourcen innerhalb Ihrer Anlage präzise abbilden.

- Komplexe Prozessabläufe modellieren und simulieren.

- Steuerlogiken in einer simulierten Umgebung optimieren und anpassen.

Fehler in einer kontrollierten, simulierten Umgebung einführen und beheben.

- Manuelle, zufällige und vorkonfigurierte Fehlerszenarien.

- Mitarbeitende in Fehlererkennung und -behebung schulen.

Zugriff auf und Steuerung von Anlagensystemen über eine browserbasierte Oberfläche.

- Echtzeit-Visualisierung von Steuerelementen und Abläufen.

- Möglichkeiten für Remote-Training und -Monitoring.

Visualisieren Sie das gesamte Anlagenlayout zusammen mit den Sensordaten.

- Echtzeit-Sensor- und Anlagendaten integrieren.

- Einen klaren und umfassenden Überblick über Ihre Abläufe bieten.

Layout-Darstellung mit Sensorinformationen.

Die leistungsstarke 3D-Simulation von RF::EdDi ermöglicht es Nutzern, mit realistischen virtuellen Modellen ihrer industriellen Prozesse zu interagieren. Bediener können die Anlagen manuell steuern, Steuerbefehle ausführen und ihre Abläufe in Echtzeit visualisieren. Diese Funktion bietet ein praxisnahes, interaktives Lernerlebnis, das reale Szenarien nachbildet und das Personal optimal auf die Anforderungen im Betrieb vorbereitet.

Die Verhaltenssimulation ermöglicht die präzise Abbildung von Anlagenressourcen und Prozessen. Mit RF::EdDi können Nutzer komplexe Abläufe simulieren, Steuerlogiken optimieren und Arbeitsabläufe in einer virtuellen Umgebung trainieren. Diese Funktionalität reduziert das Risiko von Fehlern im realen Betrieb und beschleunigt die Einführung neuer Prozesse.

Bereiten Sie Ihre Mitarbeitenden mit der Fehlersimulationsfunktion von RF::EdDi auf unerwartete Herausforderungen vor. Trainer können manuelle oder automatisierte Fehler einführen und so reale Störungen simulieren, ohne Maschinen zu gefährden. Die Mitarbeitenden sammeln wertvolle Erfahrung in der Diagnose und Behebung von Fehlern, stärken ihre Problemlösungsfähigkeiten und ihr Selbstvertrauen.

RF::EdDi unterstützt webbasierte Visualisierung und bietet damit maximale Flexibilität und Zugänglichkeit. Trainer und Bediener können Systeme über eine Web-Oberfläche aus der Ferne steuern und überwachen. Mit der WebVisu lässt sich eine realitätsnahe Benutzeroberfläche nachbilden, die eine intuitive Navigation durch bestehende Systemressourcen ermöglicht. Zudem können Funktionen wie Fehlerszenariosimulation und Fortschrittsverfolgung nahtlos in die Oberfläche integriert werden.

RF::EdDi integriert Sensordaten direkt in die Layout-Darstellung der Anlage und bietet so einen umfassenden Überblick über alle Abläufe. Diese Funktion ermöglicht es Trainern und Bedienern, die Leistung in Echtzeit zu analysieren, den Zustand der Systeme zu überwachen und einen gleichbleibenden Betrieb sicherzustellen. Durch die Kombination von Sensordaten mit dem visuellen Layout verbessert RF::EdDi das Situationsbewusstsein für industrielle Prozesse.

Die leistungsstarke 3D-Simulation von RF::EdDi ermöglicht es Nutzern, mit realistischen virtuellen Modellen ihrer industriellen Prozesse zu interagieren. Bediener können die Anlagen manuell steuern, Steuerbefehle ausführen und ihre Abläufe in Echtzeit visualisieren. Diese Funktion bietet ein praxisnahes, interaktives Lernerlebnis, das reale Szenarien nachbildet und das Personal optimal auf die Anforderungen im Betrieb vorbereitet.

Die Verhaltenssimulation ermöglicht die präzise Abbildung von Anlagenressourcen und Prozessen. Mit RF::EdDi können Nutzer komplexe Abläufe simulieren, Steuerlogiken optimieren und Arbeitsabläufe in einer virtuellen Umgebung trainieren. Diese Funktionalität reduziert das Risiko von Fehlern im realen Betrieb und beschleunigt die Einführung neuer Prozesse.

Bereiten Sie Ihre Mitarbeitenden mit der Fehlersimulationsfunktion von RF::EdDi auf unerwartete Herausforderungen vor. Trainer können manuelle oder automatisierte Fehler einführen und so reale Störungen simulieren, ohne Maschinen zu gefährden. Die Mitarbeitenden sammeln wertvolle Erfahrung in der Diagnose und Behebung von Fehlern, stärken ihre Problemlösungsfähigkeiten und ihr Selbstvertrauen.

RF::EdDi unterstützt webbasierte Visualisierung und bietet damit maximale Flexibilität und Zugänglichkeit. Trainer und Bediener können Systeme über eine Web-Oberfläche aus der Ferne steuern und überwachen. Mit der WebVisu lässt sich eine realitätsnahe Benutzeroberfläche nachbilden, die eine intuitive Navigation durch bestehende Systemressourcen ermöglicht. Zudem können Funktionen wie Fehlerszenariosimulation und Fortschrittsverfolgung nahtlos in die Oberfläche integriert werden.

RF::EdDi integriert Sensordaten direkt in die Layout-Darstellung der Anlage und bietet so einen umfassenden Überblick über alle Abläufe. Diese Funktion ermöglicht es Trainern und Bedienern, die Leistung in Echtzeit zu analysieren, den Zustand der Systeme zu überwachen und einen gleichbleibenden Betrieb sicherzustellen. Durch die Kombination von Sensordaten mit dem visuellen Layout verbessert RF::EdDi das Situationsbewusstsein für industrielle Prozesse.

Die leistungsstarke 3D-Simulation von RF::EdDi ermöglicht es Nutzern, mit realistischen virtuellen Modellen ihrer industriellen Prozesse zu interagieren. Bediener können die Anlagen manuell steuern, Steuerbefehle ausführen und ihre Arbeitsabläufe in Echtzeit visualisieren. Diese Funktion bietet ein praxisnahes, interaktives Lernerlebnis, das reale Szenarien nachbildet und das Personal optimal auf die Anforderungen im Betrieb vorbereitet.

Die Verhaltenssimulation ermöglicht die präzise Abbildung von Anlagenressourcen und Prozessen. Mit RF::EdDi können Nutzer komplexe Abläufe simulieren, Steuerlogiken optimieren und Arbeitsabläufe in einer virtuellen Umgebung trainieren. Diese Funktionalität reduziert das Risiko von Fehlern im realen Betrieb und beschleunigt die Einführung neuer Prozesse.

Bereiten Sie Ihre Mitarbeitenden mit der Fehlersimulationsfunktion von RF::EdDi auf unerwartete Herausforderungen vor. Trainer können manuelle oder automatisierte Fehler einführen und so reale Störungen simulieren, ohne Maschinen zu gefährden. Die Mitarbeitenden sammeln wertvolle Erfahrung in der Diagnose und Behebung von Fehlern, stärken ihre Problemlösungsfähigkeiten und ihr Selbstvertrauen.

RF::EdDi unterstützt webbasierte Visualisierung und bietet damit maximale Flexibilität und Zugänglichkeit. Trainer und Bediener können Systeme über eine Web-Oberfläche aus der Ferne steuern und überwachen. Mit der WebVisu lässt sich eine realitätsnahe Benutzeroberfläche nachbilden, die eine intuitive Navigation durch bestehende Systemressourcen ermöglicht. Zudem können Funktionen wie Fehlerszenariosimulation und Fortschrittsverfolgung nahtlos in die Oberfläche integriert werden.

RF::EdDi integriert Sensordaten direkt in die Layout-Darstellung der Anlage und bietet so einen umfassenden Überblick über alle Abläufe. Diese Funktion ermöglicht es Trainern und Bedienern, die Leistung in Echtzeit zu analysieren, den Zustand der Systeme zu überwachen und einen gleichbleibenden Betrieb sicherzustellen. Durch die Kombination von Sensordaten mit dem visuellen Layout verbessert RF::EdDi das Situationsbewusstsein für industrielle Prozesse.

Risikominimierung

Reduzieren Sie das Risiko von Fehlern und potenziellen Problemen durch Simulation.

Kollisionsvermeidung

Mit dem Interlock-Check können potenzielle Kollisionen identifiziert werden, bevor sie auftreten.

Verkürzung der Hochlaufzeit

Planen Sie Ihre Anlage vorab durch Simulation und reduzieren Sie so die Hochlaufzeit der Produktion.

Mechanischer und PLC-Schutz

Schützen Sie Roboter-, mechanische und PLC-Komponenten und verhindern Sie potenzielle Probleme.

Frühe Sonderfunktionsprüfung

Testen Sie spezielle Anforderungen und Funktionen, bevor die Anlage live geschaltet wird.

Lieferantenkontrolle

Erhalten Sie Kontrolle über Ihre Lieferanten, indem Sie Ihre Produktion vollständig simulieren und testen.

Kosteneffizienz

Sparen Sie bei Trainingsaufbauten und Equipment durch virtuelle Simulationen.

Reduzieren Sie den Flächenbedarf für Trainingszentren.

Flexibilität und Zugänglichkeit

Trainieren Sie jederzeit und überall mit webbasierter Lösung.

Passen Sie Trainingsprogramme einfach an spezifische Fähigkeiten und betriebliche Anforderungen an.

Realistische Simulation

Nutzen Sie Digital-Twin-Technologie für realitätsnahe Trainingsszenarien.

Ermöglichen Sie detaillierte 3D- und Verhaltenssimulationen für ein immersives Lernen.

Verbessertes Lernerlebnis

Interaktive Module binden Teilnehmende in praxisnahe Trainingsszenarien ein.

Bieten Sie sofortige Leistungsbewertungen und Feedback zur Verbesserung des Lernfortschritts.

Sicherheits- und Risikomanagement

Üben Sie an virtuellen Anlagen, um reale Risiken zu vermeiden.

Simulieren Sie Fehler und Notfälle in einer kontrollierten Umgebung.

Verbesserte Betriebseffizienz

Bereiten Sie Mitarbeitende auf neue Prozesse vor der Einführung vor.

Überwachen Sie Trainingsfortschritte, um langfristige Kompetenzsteigerung sicherzustellen.

RF::EdDi ist ein fortschrittliches virtuelles Trainingswerkzeug, das realistische, interaktive Trainingsszenarien für industrielle Prozesse bietet. Es nutzt 3D-Simulationen, Verhaltensmodellierung und Fehlersimulation, um Mitarbeitende in einer sicheren, kontrollierten Umgebung zu schulen und Betriebsabläufe zu optimieren.

RF::EdDi ermöglicht es Mitarbeitenden, an komplexen Maschinen und Prozessen zu trainieren, ohne physisches Equipment zu benötigen. Zu den Funktionen gehören realistische 3D-Modelle, Verhaltenssimulation und anpassbare Trainingsszenarien, die ein praxisnahes und immersives Lernerlebnis bieten.

Ja, RF::EdDi bietet Funktionen zur Fehlersimulation, mit denen Nutzer manuelle, zufällige oder vorkonfigurierte Fehlerszenarien einführen können. So werden Mitarbeitende in Fehlererkennung, Fehlersuche und -behebung geschult und optimal auf reale Herausforderungen vorbereitet.

RF::EdDi ermöglicht es Nutzern, Trainingsprogramme individuell an spezifische Anforderungen, Qualifikationsniveaus und branchenspezifische Vorgaben anzupassen. Szenarien, Abläufe und Simulationen können flexibel für die jeweiligen Anwendungen gestaltet werden.

RF::EdDi stellt sicher, dass Trainings in einer vollkommen risikofreien Umgebung stattfinden. Mitarbeitende können an virtuellen Systemen üben, ohne reale Anlagen zu gefährden oder sich selbst in Gefahr zu bringen.

Unsere Produktpalette umfasst vielfältige Werkzeuge – von SPS- und Roboteranschlüssen bis hin zu fortschrittlicher Automatisierung und Schulungsressourcen. Im Kern steht dabei eine zentrale Tool-Suite, die alle Komponenten nahtlos verbindet und so ein leistungsstarkes, durchgängiges System schafft.

Simuliert Produktionssysteme in einer 3D-Virtual-Environment und liefert detaillierte Einblicke in Systemleistung, Optimierungspotenziale und Betriebseffizienz.

Modelliert, simuliert und testet Peripheriekomponenten in der virtuellen Inbetriebnahme – mit wiederverwendbaren Programmbausteinen für mehr Flexibilität und Effizienz.

Bietet fortschrittliche Robotersimulation zur Prüfung und Optimierung von Roboterprogrammen – für fehlerfreie Inbetriebnahme und effiziente Abläufe.

Analysiert Produktionsdaten aus virtuellen und realen Systemen, um Engpässe zu erkennen, die Leistung zu optimieren und die Produktionseffizienz zu steigern.

Automatisiert die 3D-Vorrichtungsplanung mit bearbeitbaren Modellen – für maximale Flexibilität der Konstrukteure und optimierte Produktionsabläufe.

Simuliert Profinet-Geräte für die virtuelle Inbetriebnahme und ermöglicht nahtloses Testen mehrerer SPS-Steuerungen in einer einzigen Umgebung.

Unsere Produktpalette umfasst vielfältige Werkzeuge – von SPS- und Roboteranschlüssen bis hin zu fortschrittlicher Automatisierung und Schulungsressourcen. Im Kern steht dabei eine zentrale Tool-Suite, die alle Komponenten nahtlos verbindet und so ein leistungsstarkes, durchgängiges System schafft.

Simuliert Produktionssysteme in einer 3D-Virtual-Environment und liefert detaillierte Einblicke in Systemleistung, Optimierungspotenziale und Betriebseffizienz.

Modelliert, simuliert und testet Peripheriekomponenten in der virtuellen Inbetriebnahme – mit wiederverwendbaren Programmbausteinen für mehr Flexibilität und Effizienz.

Bietet fortschrittliche Robotersimulation zur Prüfung und Optimierung von Roboterprogrammen – für fehlerfreie Inbetriebnahme und effiziente Abläufe.

Analysiert Produktionsdaten aus virtuellen und realen Systemen, um Engpässe zu erkennen, die Leistung zu optimieren und die Produktionseffizienz zu steigern.

Automatisiert die 3D-Vorrichtungsplanung mit bearbeitbaren Modellen – für maximale Flexibilität der Konstrukteure und optimierte Produktionsabläufe.

Simuliert Profinet-Geräte für die virtuelle Inbetriebnahme und ermöglicht nahtloses Testen mehrerer SPS-Steuerungen in einer einzigen Umgebung.

Analysiert Produktionsdaten aus virtuellen und realen Systemen, um Engpässe zu erkennen, die Leistung zu optimieren und die Produktionseffizienz zu steigern.

Haben Sie eine Projektidee?

China,

Shanghai

Deutschland,

Weingarten

Bosnien,

Tuzla

Indien,

Bangalore

Montenegro,

Podgorica

China, Shanghai

Deutschland, Weingarten

Bosnien, Tuzla

Indien, Bangalore

Montenegro, Podgorica

Wir verwenden Cookies und andere Tracking-Technologien, um Ihr Nutzungserlebnis auf unserer Website zu verbessern, personalisierte Inhalte und gezielte Werbung anzuzeigen, den Website-Traffic zu analysieren und zu verstehen, woher unsere Besucher kommen.